Email Us:

Email Us:- disk-aerator@hotmail.com

- To share:

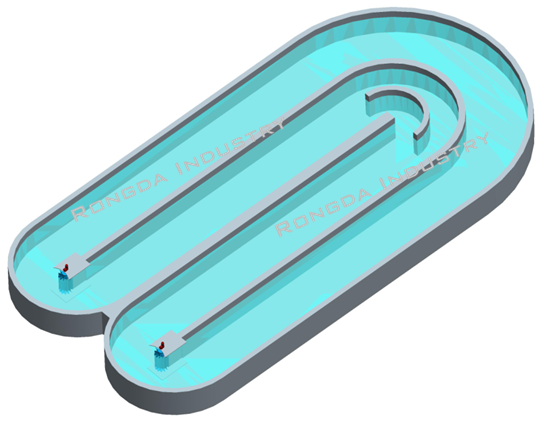

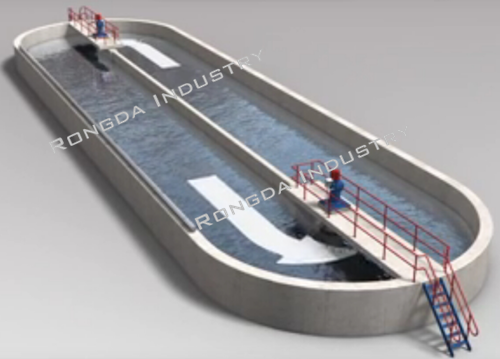

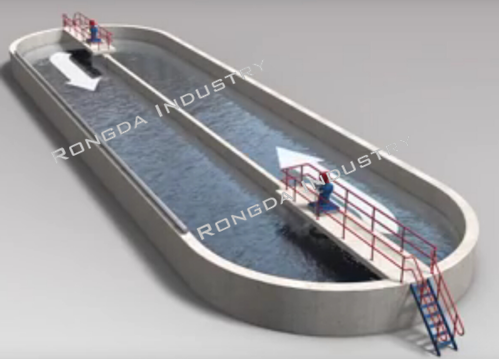

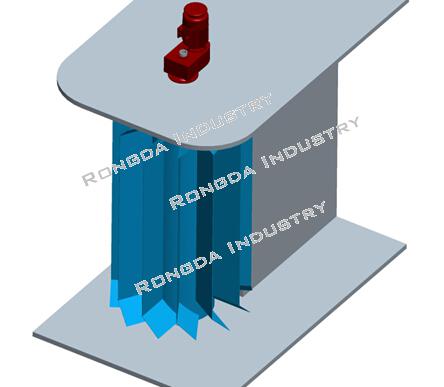

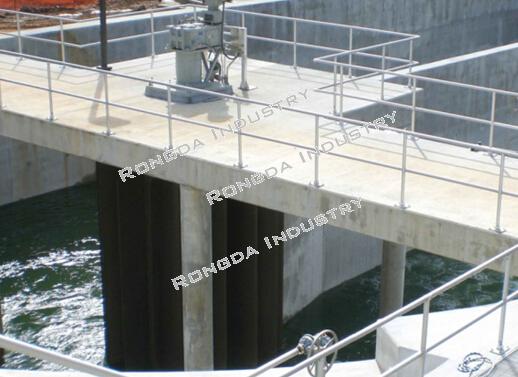

The vertical UT flow accelerator or boosters apply in the oxidation ditch process (channel aeration), flow boosters installation and maintenance are flexible, reliable running, good performance, operating costs and running noise very low.

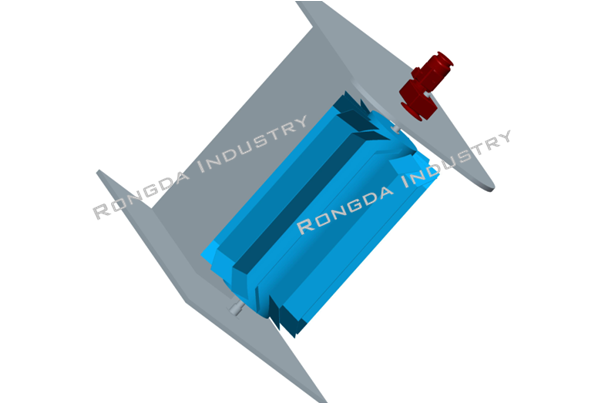

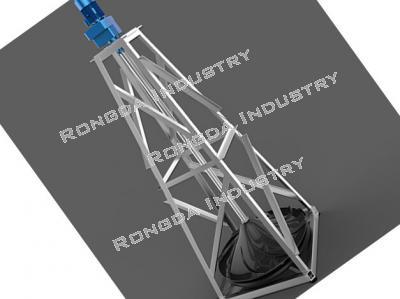

Propulsion is effected by one or more low speed vertical U type paddle, positioned in de bends of the aeration circuit.

The flow booster rotors are suspended on specially designed Outriggers extended, bearing life is maximized. Therefore the application of submerged lower bearings is no longer necessary.

Aeration takes place by means of diffusers (ceramic, plastic or membrane) mounted on the bottom of the aeration circuit.

UT flow accelerator or boosters features and advantage:

High oxygen transfer (3.8 to 4.5 kg O2/kWh);

Low propulsion energy (1.0 to 1.8 W/m3);

High overall efficiency; lower diffuser density

No velocity gradients over the water depth

No "dead" zones

Less complicated control systems

Lower propulsion energy required

No moving parts in the water

No sensitivity to fouling

Low maintenance and construction costs because of simple channel layout

Optimal process control by adjustment of aeration capacity, independing on propulsion

Denitrification is simply realised

Applicable in existing circuits with surface aerators

Aypical application

Chunqiu Road 2#, Hutang Town, Changzhou City, Jiangsu Province

Chunqiu Road 2#, Hutang Town, Changzhou City, Jiangsu Province +86-519-86538239

+86-519-86538239

Skype1

Skype1

Comments List