Email Us:

Email Us:- disk-aerator@hotmail.com

- To share:

DTRO System

DTRO (Disk Tubular Reverse Osmosis), is a patented membrane separation equipment.

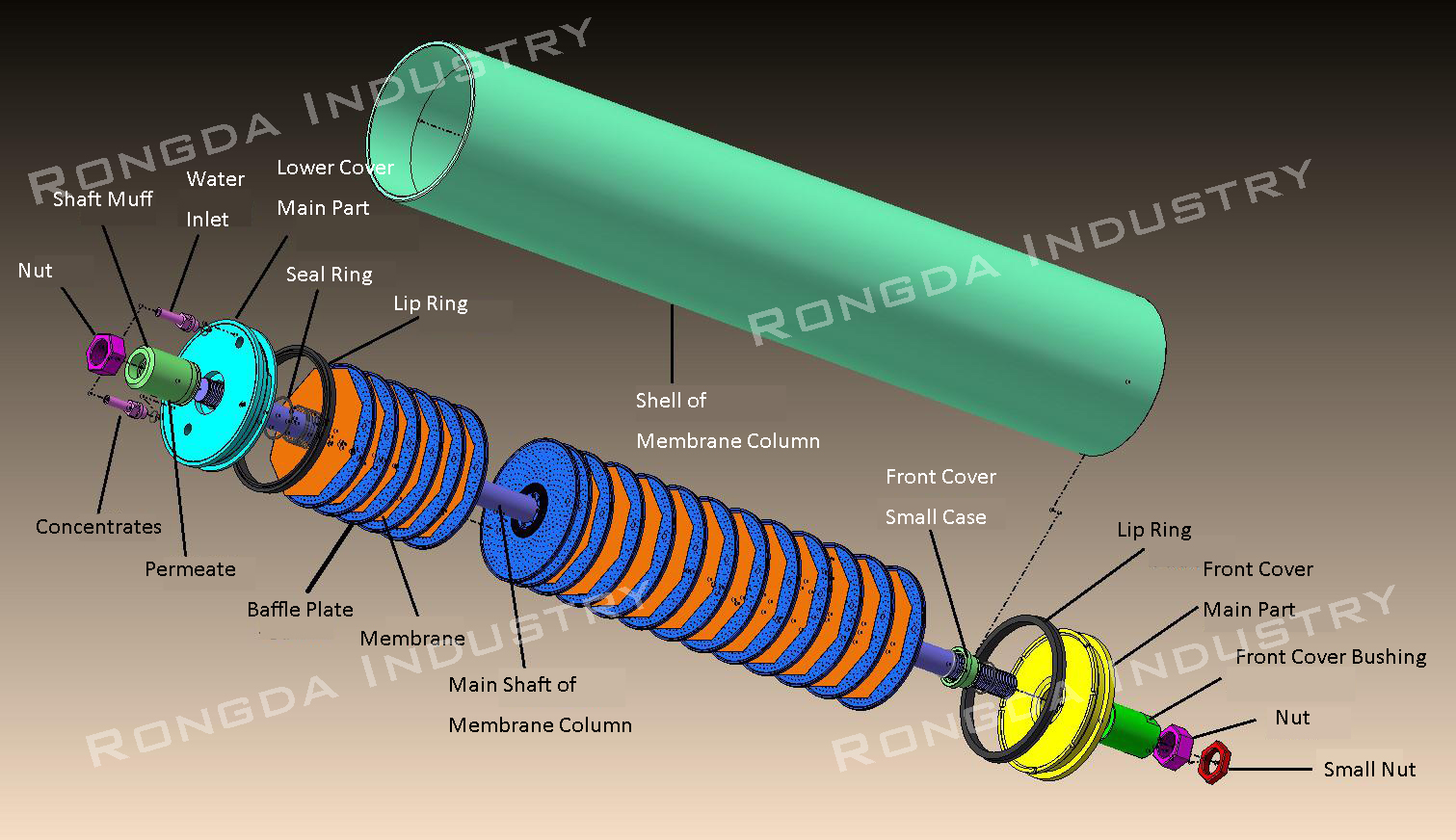

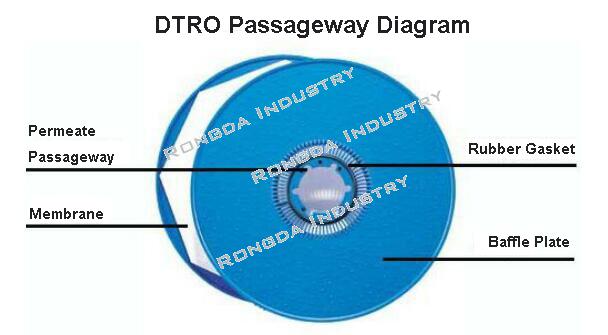

Its membrane structure is different from the traditional roll film. Original fluid passageway: DTRO flow channel is a patent design with the form of an open flow path. Feed liquid goes into the pressure vessel through the inlet, from the passageway between baffle plate and housing to the other side. In the flange of other side, feed liquid goes in to baffle plate. Treated liquid goes the shortest distance through the filter membrane quickly and then goes to the other side of the membrane with 180 degree. It goes into next baffle plate from the centre of former baffle plate. The whole process form a double "S" shaped route which is from circumference of baffle plate to the center of a circle, then with one more repetition of the same routine. Finally the concentrate flows out from the feed end flange. The distance of two baffle plate of DTRO is 4mm. There are radioactive rays arranged in a certain way on the surface of baffle plate. This special hydraulic design allows the treatment liquid form the turbulent water flows under pressure through the membrane surface crashing radiation to increase permeation rate and self-cleaning function. It effectively avoids the clogging of the membrane and concentration polarization phenomena, successfully extending the service life of membrane. It is easy to clean the fouling to ensure DTRO suitable for a high sand content and high turbidity coefficient wastewater treatment and for the worse conditions.

Permeate flow path: filter membrane consists of tow concentric annular reverse osmosis membrane with a layer of silk scaffold in the middle of membrane, which makes the water flow quickly through the membrane to the outlet. The outer ring of three ring material is welding by ultrasonic technique, with inner opening for water exports. Permeate flows to the peripheral permeate channel outside the central rod along the silk scaffold. O-type seal ring on the baffle plate is to prevent raw water from entering into the permeate passage. The distance of permeate liquid from the membrane to the center is very short and is the same for all the filter membrane in components.

The selection process should consider the following basic requirements, especially for water features of landfill leachate:

(1) A high COD removal capability;

(2) High-load treating capability;

(3) Adapt to leachate concentration fluctuations in different seasons;

(4) Leachate treatment facilities must operate during the winter;

(5) The process is simple with the small footprint;

(6) Under the premise to meet the emission standards, the choice of most economical investment, the lowest operating costs and the best treatment technology;

(7) The process is safe and non-polluting;

(8) The treatment facilities operate stable and easy operation and management;

(9) Consider the current status of leachate as well as the long-term changes of water quality and quantity.

Flushing and Cleaning of the Equipment

There are two types of membrane cleaning which is flushing and chemical cleaning.

DTRO system includes cleaning agent A, cleaning agent C, scale inhibitor and cleaning buffer tank. The operator needs to periodically add the cleaning agents and inhibitors to tank and set the cleaning execution time. The system can be cleaned automatically when it needs.

System Flushing

Flushing of membrane group are running each time when system shutdown. When the system needs to stop at normal running state, it usually cleans first and then stops. When the system failures and automatically shut down, a flushing procedure is also performed. The main purpose of flushing is to prevent that leachate contaminants deposited on the surface of the diaphragm. Flushing is divided into two types. One is flushing with leachate and the other flushes with clean water. Two flushing time can be set on the user interface which is usually 2-5 minutes.

Chemical Cleaning

To maintain the performance of the membrane, the membrane group should be periodically chemically cleaned. Cleaning agents are acidic cleaners and alkaline cleaners. The major role of alkaline cleaners is to clear organic pollution while the acid cleaning agent is to remove inorganic contamination.

When cleaning, the cleaning solution circulates in the membrane group system to remove the contaminants deposited on the diaphragm. The cleaning time is usually 1-2 hours, but it can be terminated at any time. After completion of the cleaning, the liquid discharge to the conditioning tank. Chemical cleaning of the membrane group is controlled automatically by the computer system. The cleaning parameters can be set on the computer screen.

Cleaning agents are generally diluted to 5-10%.

Cleaning Cycle

Cleaning time interval depends on the concentration of pollutants in the water. When the water under the same conditions, permeate of the membrane system is reduced by 10% to 15% or the membrane inlet and outlet pressure differential exceeds the permitted set value (DT inlet and outlet pressure permeate is 12bar. Roll RO membrane tube inlet and outlet pressure is 2.5bar.). The system needs to be cleaned. The cleaning cycle under normal circumstances is as following:

Chemical cleaning cycle of the first DT system:

Caustic: 5 days pH = 10 ~ 11

Pickling: 10 days pH = 2.5 ~ 3.5

Chemical cleaning cycle of the second DTRO system:

Caustic: 14 days pH = 10 ~ 11

Pickling: 28 days pH = 2.5 ~ 3.5

Chunqiu Road 2#, Hutang Town, Changzhou City, Jiangsu Province

Chunqiu Road 2#, Hutang Town, Changzhou City, Jiangsu Province +86-519-86538239

+86-519-86538239

Skype1

Skype1

Comments List