Email Us:

Email Us:- disk-aerator@hotmail.com

- To share:

Detailed Product Description

The submersible hyper classic high efficiency mixing and fast (perfect) aeration technology is widely used in water purification and wastewater treatment processes, In the process of the whole water purification, water mixing and stirring process are the most important processes. For example, in the municipal sewage, living wastewater, chemical wastewater, paper and steel and other water purification and treatment process are being used in mixing and stirring technology. And early most of the sewage treatment plant using impeller is double bladed paddle or multi blade, blade mixing technology, both in terms of energy consumption or in the mixing effect are not ideal, to the sewage treatment plant a substantial increase in the energy consumption and operation cost, equipment maintenance costs, and will lead to the water purification effect of decreased and standards and other serious problems.

RONGDA industry group's rongda electronics (environmental division) is engaged in the field of water treatment for more than 20 years, has been concerned with improving water treatment by stirring and mixing, aeration (O2-transfer) and mixing are combined technology, the company with a number of water treatment Research Institute jointly developed a variety of perfect stirring, mixing, aeration equipments, the equipment of stirring, mixing and aerating effect very ideal, energy consumption reduced by 65%, equipment maintenance costs reduced by 50%, mixing effect is increased by 50%.

Through 20 years of practice and thousands of engineering cases, RONGDA INDUSTRY 's Mixing and stirring equipment, mixing and aeration combined system get the recognition and support in more than 30 countries in the world.

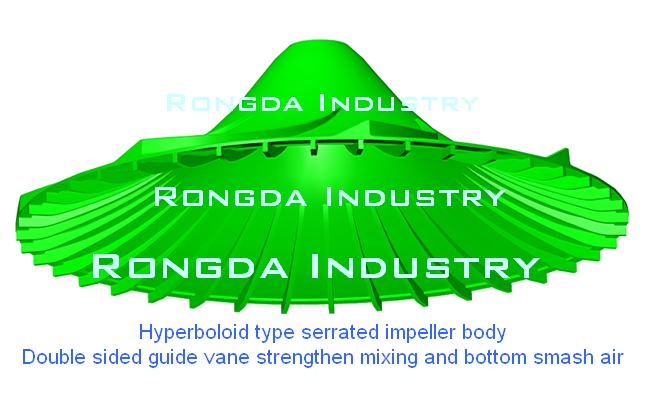

RONGDA INDUSTRY efficient and perfect mixing and aeration outstanding works is hyperboloid mixing aeration combination systems, this product is RONGDA INDUSTRY 's hyper classic mixers aerators works.

The low speed submersible mixer and aeration systems common alias:hyperboloid stirrer aerator,hyperdive mixer aerator,hyperboloid mixer aerator,hyperbolic mixer aerator,hyperclassic mixer aerator,invent mixer aeration system,invent hyperclassic aeration system,hypercage mixer aerator,wastewater mixer and aerator.

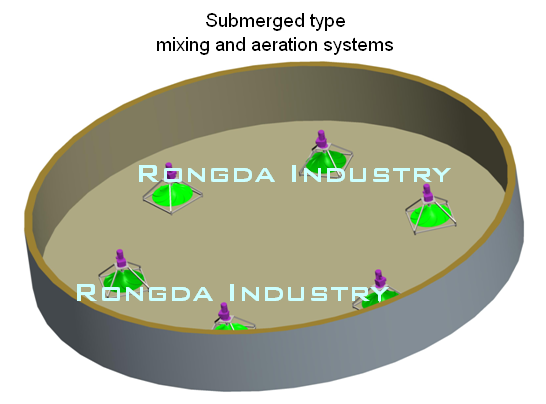

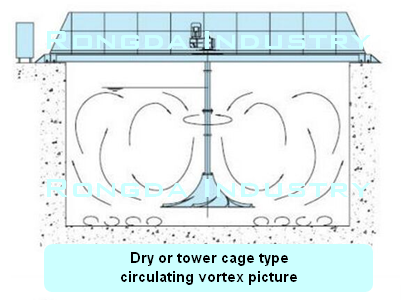

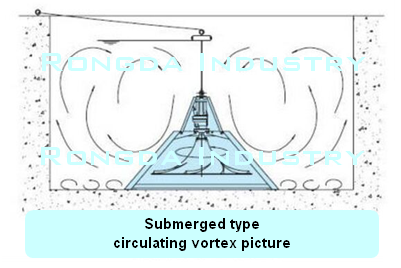

Low speed submersible hyperboloid mixing and aeration combination systems is submerged type hyper dive hyperboloid mixers aerators systems, agitators working in tanks bottom, will be liquid mixing and aeration (Oxygen supply);

Product structure and advantages

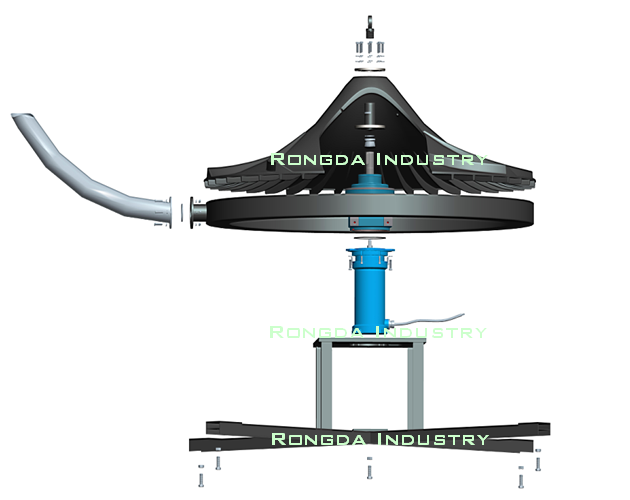

RONGDA INDUSTRY 's mixing and aeration systems is made of hyper classic hyperboloid impeller body, stainless steel shaft, gearbox motor and bottom bearing etc combinations.

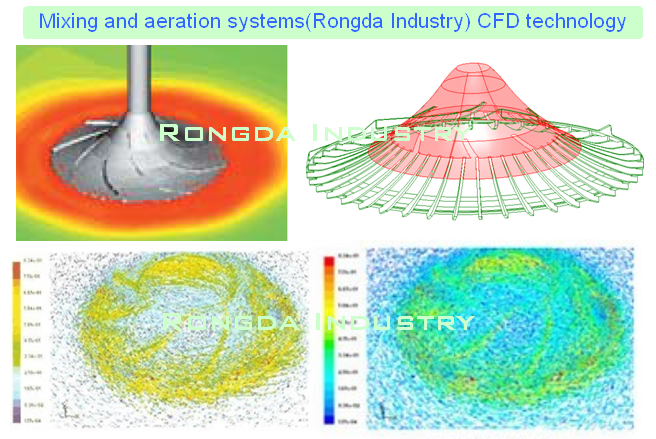

RONGDA INDUSTRY's mixers and aerators systems has excellent mixing and aeration performance, hyperboloid turbine body uses the most advanced (CFD) computational fluid dynamics and (FEM) finite element method design technology, and according to many years of accumulated technology and accurate measurement of continuous optimization design, ultimately create a perfect hyperboloid mixing aeration systems. The mixers and aerators has unique design of hyperboloid turbine body,at tanks any position can be highly efficient mixing aeration and low energy consumption and maintenance-free under the condition normal operation. RONGDA INDUSTRY’s mixing and aeration technology is better than the conventional surface aeration and jet aeration,discs type membrane diffuser etc.

RONGDA INDUSTRY mixers and aerators systems at In the low speed mixing and fine bubble aeration process can form the tens of thousands of high speed rotating eddy current and fine bubble,tanks any position no sedimentation and tanks generated intense vortex flow (Stirring no dead zones).the hyperboloid mixers aerators systems energy consumption is very low, in activated sludge tank only 2 W / m3, because the alpha factor value is more than 0.9 , oxygen conversion efficiency is close to perfection, the test value is as high as 3KgO2/m3(All the pure water condition).

Product application and case description

RONGDA INDUSTRY's low speed submersible mixer and aerator systems widely used in wastewater treatment processes; Such as-Sequenced Batch Reactors(SBR),Activated Sludge Reactors(aeration tanks),Moving Bed Biofilm Reactor (MBBR),Submerged Aerated Filter(SAF),Suspended Media Filters(SMF),Aerobic Sludge Stabilisation,Neutralization Tanks,Precipitation Tanks,Coagulation Tanks,Denitrification Tanks,BOD or COD Removal Reactors,Disinfection Reactors,Storage of Chemicals or Chemical Solution,Buffer Tanks for Equalisation Tank,Anaerobic Reactors,Flocculation Reactors,Thermophilic Sludge Reactors,Alternating Biological Reactors,Anaerobic Sludge Digesters,Sludge Storage tanks and Sludge Stabilisation Reactors etc.

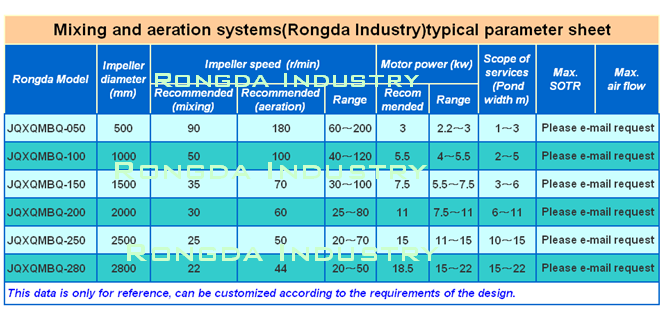

Mixing and aeration systems(Rongda Industry)typical parameter sheet

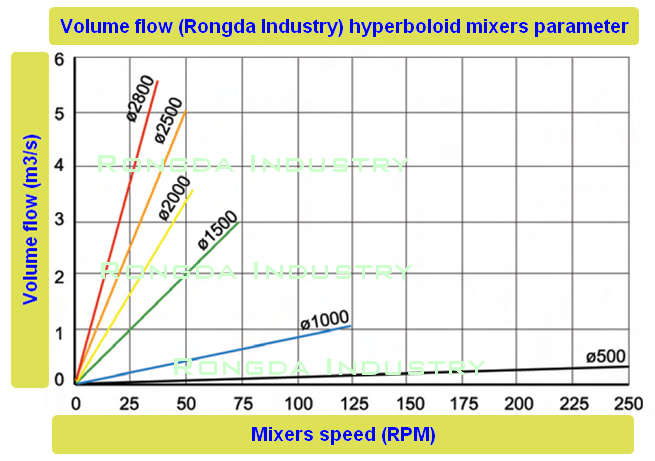

Volume flow (Rongda Industry) hyperboloid mixing and aerator systems

Just as special structure of mixers impeller and feature of tank bottom-close installation, its working location decides direct anti-settling function of suspended substances. It can achieve ideal mixing effect when working and effectively remove mixing blind angle. Large surface area lets water body exchange at large area. When using, the hyperboloid mixing impeller mixes water body to make water body flow along circumferential direction and turn over up and down, thereby mixing the water flow in all direction and spirally, ensuring uniform mixing between solid and liquid, liquid and gas, and among solid, liquid and gas, and removing blind angle. The hyperboloid impeller is especially fit for round tank and square tank, and several impellers can be allocated in rectangle tank.

Chunqiu Road 2#, Hutang Town, Changzhou City, Jiangsu Province

Chunqiu Road 2#, Hutang Town, Changzhou City, Jiangsu Province +86-519-86538239

+86-519-86538239

Skype1

Skype1

Comments List